Diamond's new line of forged diesel pistons for Duramax and Power Stroke applications are designed for big boost and stump-pulling power.

Diamond Racing Pistons is an acknowledged leader in racing piston design, but many may be unaware that Diamond also applies its considerable engineering expertise to the commercial and consumer diesel market. It offers a full line of upscale forged replacement pistons incorporating desirable performance and durability features long recognized as a hallmark of Diamond racing pistons. Diamond’s broad selection covers 6.6L GM Duramax engines from 2000 through 2011 and Ford PowerStroke engines from 1994 through 2007. PowerStroke coverage includes both the 7.3L and 6.0L V8 diesels from Ford. In additon, Diamond has a large selection of Cummins pistons.

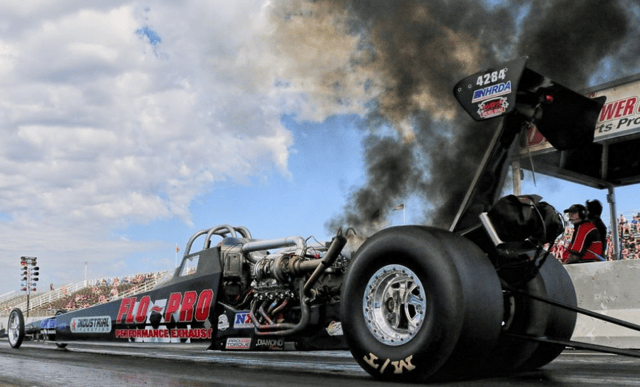

Truck owners are leaning on these engines harder and harder with severe racing and towing requirements that often match or exceed the manufacturer’s recommended maximum limits. To gain more performance they frequently modify engines with upgraded fueling and tuner components that operate the engines beyond original design specs. Recognizing this common practice, Diamond also noted that diesel engine repair and rebuilding shops needed upscale replacement pistons that exceed OEM specs and meet the special needs of consumers who push their vehicles to the limit.

Engine shops that service the diesel market and performance-seeking specialty builders are increasingly turning to Diamond to help address common piston issues brought about by those operating practices that exceed OEM recommendations. Many of the standard features unique to Diamond diesel replacement pistons are solving and eliminating performance flaws common to of OEM pistons. They include:

- Made from Billet 2618 alloy - For the Ultimate in Piston Strength

- Double Diamond Coating - Offers Extreme Durability

- Designed for Factory Compression Ratios

- DLC Coated H13 Material Wrist Pins Included

- OEM Style Replacement Pistons Available in Multiple Oversize’s

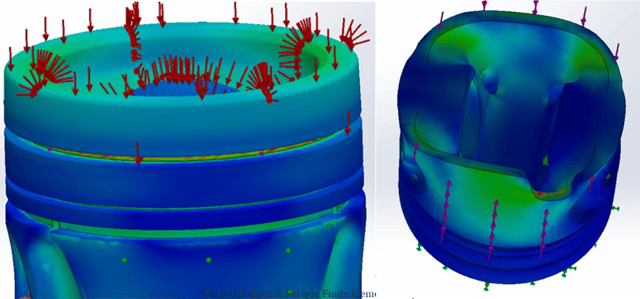

While diesel engine manufacturers have built in a pre-specified level of durability, it has frequently proved insufficient to accommodate end user abuse. Overheating, lubrication and fueling issues are the root cause of many of the problems. Diamond’s billet 2618 alloy helps solve heat related dimensional problems by providing pistons that are thermally stable with predictable growth characteristics and the necessary strength to absorb the stress of severe usage. The pistons are also double Diamond coated to reduce friction and eliminate piston skirt to cylinder wall distress. The piston coating process ensures optimum protection against the severe heat associated with diesel operation and the over-fueling and potential fuel-wash damage that may result from enthusiasts seeking greater performance.

Diamond’s diesel pistons also incorporate heavy duty H13 wrist pins treated with its proprietary PVD Diamond Like Carbon coating (DLC) to eliminate galling and lubrication issues under severe loading. The wrist pin is literally a pivotal component at the heart of the most severe conditions in the engine. While the rod is either in tension or compression, the wrist pin experiences extreme bending moments on every stroke. The DLC coating is ideal for combating the friction and lubrication issues that accompany these severe operating conditions.

Diamond's Diesel Program Manager JJ Zimmerman described the development and manufacturing of its diesel pistons as a process that pays close attention to detail regarding structural integrity and design features that help the piston support the combustion process more efficiently. While off-the-shelf rebuild pistons are a staple, Diamond is also heavily invested in the diesel racing market which incorporates a broad variety of very demanding performance applications.

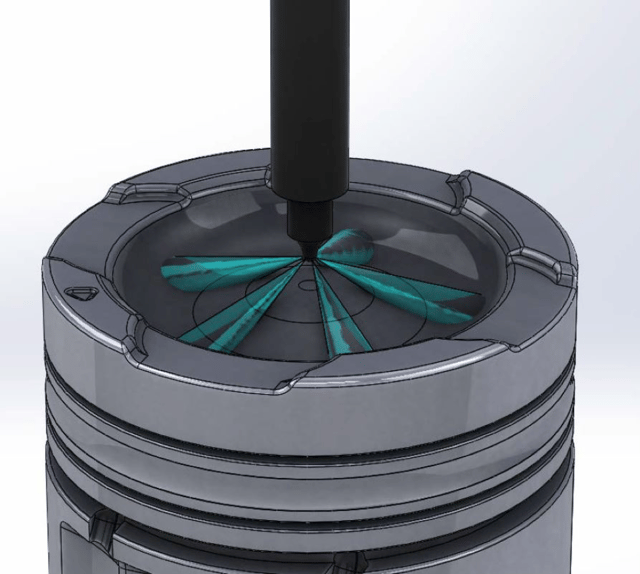

According to Zimmerman, "A Diamond Racing piston's bowl is carefully configured to prioritize an even burn. The goal is to achieve and maintain the most efficient burn rate possible. On a 6.7-liter Cummins, for example, we'll "de-lip" the factory bowl slightly, reduce the quench pad and add a slight reversion lip (kick-back, or undercut) which has proved effective in the real world by generating a better flame front and increasing horsepower for drag racing applications.

Zimmerman further reminds us that Diamond also manufactures a premium upgraded wrist pin with its proprietary TP1 (Trend Performance 1) tool steel material. This material permits reduced sectional wall thickness, further eliminating weight, but without sacrificing strength for those seeking an extremely light, but highly durable rotating assembly.

Performance improvements in replacement pistons are primarily incorporated for durability reasons. It is commonly agreed that a good rebuild piston will be manufactured to OE specifications to ensure the best performance and meet federal emission standards. Diamond follows this practice to ensure maximum compatibly. Diamond makes all its forged replacement pistons match the original factory compression ratio.

The pistons are offered in standard, plus ten (.010) and plus twenty (.020) bore sizes to accommodate standard rebuilds. They have thick, full round skirts and heavy-duty pin bosses with critical pin oiling features and oil return holes to promote improved piston cooling. Diamond precision machining is also applied to the piston ring grooves to ensure that the rings are fully supported and stabilized for optimum sealing under extreme cylinder pressures. Rebuilder shops are turning to Diamond for pistons that solve common issues and eliminate “come backs” that are the bane of engine shop profitability.

As a top tier engineering and manufacturing company, Diamond is always open to addressing different requirements. "If we know there are known issues, we address those first before other pistons design changes are made. Diamond does a lot of prototype work and it has been able to accommodate some extravagant bowl and piston designs. the company maintains a full data base of OEM bowl profiles so if someone was to stick with what they know, Diamond can accommodate those needs, or provide customers with their own "exclusive dish profile" if needed for a specific application.

Commenting on the difference between billet and forged designs, Zimmerman says that billets provide the flexibility to make almost any configuration required, but the similarities in terms of durability are very close. "Billet allows us to be flexible to the end user, to where we can make anything by changing the dish design, volume figures, and ring land locations. The material strength between the two is almost the identical."

Skirt designs are specifically unique to the company, as Zimmerman revealed. "We have a couple of different designs that we use for the diesel lineup," he said. "We are pretty happy with them. We have enough real-world data that has allowed us to configure a unique skirt profile that we're very proud of."

A further point of pride for Diamond Racing is its surface treatments and coatings. "We do everything in-house," said Zimmerman. "Once a piston is ready, it goes straight to our coating department, where it gets prepped for coating. We can give it our hard-anodized coating, which is our most popular coating that can handle extreme heat and pressure. We also have our 'gold' coating for the piston crown, which is a blend that we found to be most effective in terms of thermal ceramic crown coatings."

"Coatings are all application-based For a drag or sled puller, it's going be different from that of a daily driven street truck. The goal of the coating is to reflect as much heat as possible off of the crown, since aluminum will heat-soak with enough exposure. We can do this thanks to the ceramic-like nature of the coating. The result is less temperature and corrosion wear to the piston and piston rings, which equates to freeing up horsepower."

CONTROLLED COMBUSTION

The combustion process takes place in the “bowl” area seen on the piston crown. Engine manufacturers incorporate different bowl shapes and sizes to accommodate various applications and emissions requirements. Higher operating temperatures and cylinder pressures exert tremendous pressure and loading on the piston crown, up to 130 bar which is generally considered the maximum for an aluminum piston. The crown is one area where failures can occur, so crown configuration is closely controlled. Piston manufacturers are keen to preserve durability under ever increasing loads, hence they largely adhere to OEM specs while adding their own unique engineering tweaks to improve durability., particularly as it relates to the piston’s ability to survive abnormal operation or extended high load usage.

Diesel engines are commonly thought to be nearly indestructible due to their robust construction and ability to operate with very high compression ratios, elevated temperatures and poor lubrication environments. A century of over-the-road trucking has long since identified common problems and modern controls have helped to curb them. Thermal overload has always been a primary problem and it is exacerbated by improper fueling and piston cooling via lubrication. Many of these problems still plague performance builders who regularly exceed all recommended limits.

Abnormal combustion events can be caused by many factors such as the air-fuel mixture in the combustion chamber being too rich. Piston crown failures in the manner of chunking, melting or crown erosion around the perimeter are primarily caused by an over-rich mixture and reduced air supply. Thermal expansion is more pronounced with aluminum pistons, requiring additional clearance in the cylinder. If clearance is insufficient, they can seize in the bore. Again, Diamond's coating helps resist this, but proper clearances are essential to diesel operation. Excessive temperature (heat) is the number one reason for deadly piston seizure. This usually comes from improper cooling and heavy towing, particularly on long grades. Diamond's diesel pistons provide the maximum protection available, but it is essential that a proper cooling system be maintained always.

Damage and complete failure from overheating is typically accompanied by crown failure, excessive fuel wash, scuffed rings or total seizure at the skirt or ring pack. Diamond has taken great care to address all these concerns with its diesel piston designs. When fuel delivery and duration is incorrect failure often ensures. Secondary causes often include contamination of the fuel and lubricants which can clog nozzles and alter proper operation. Diamond’s specialty pistons cannot cure these problems, but they can help the engine endure and survive until they are identified and corrected. Survivability thus becomes a major asset in dealing with end user abuse. Diamond’s piston survivability percentage is markedly higher than factory pistons that are bought by the millions from the lowest bidder.

Diesel rebuilds are exceedingly expensive. Performance enthusiasts by nature accept the risk and accommodate the issues. But the clear majority of DuraMax and PowerStroke users are pulling campers, horse trailers, race car trailer and the like. They count on the reliability and torque of the diesel to move them and their ware to their destination without issue, hence the need for the most robust piston possible to safely deal with any abnormal conditions that may be encountered.

We also spoke at length with engine builder David Basham of Basham Motorsports in San Bernardino, California. His specialty performance shop handles everything from Subaru cylinder head repairs to racing engines making well over a thousand horsepower. He was the engine builder for the 220 MPH Gale Banks diesel pickup truck that set production records at Bonneville. Basham rebuilds a lot of Duramax and PowerStroke engines and has seen all the problems they encounter in everyday operation and in high performance applications. Having seen both ends of the diesel performance spectrum, he provided further insight into common diesel problems he has encountered. He said there are many external factors that can also cause failures including clogged oil coolers and bad EGR function.

Recently he has seen a rash of cracked pistons, particularly on later DuraMax engines where the factory implemented a pin bushing that removed too much material from the pin boss to maintain optimum strength. He cited proper clearances, cooling oil control and maintaining the factory tune up as important factors. A lot of customers want a guarantee while they are running an aftermarket tuner package. He can’t do that because it is unfamiliar territory and he can’t be responsible for what a secondary tuner does to the engine. Diamond’s additional performance and durability features help provide the peace of mind he needs when customer engine abuse tends to begin as soon as the key is turned.

Diamond’s pistons are engineered to address all the common issues as much as possible. The company builds in additional strength and durability because they know people are going to abuse these engines. These features go a long way toward protecting the engine from damage. If the customer maintains a proper factory tune and takes steps to avoid or minimize overheating and lubrication problems they will help ensure maximum reliability and performance from Duramax and PowerStroke vehicles.