It all started in the '60s and now, Sassy Racing engines is a supercharged, Hemi powerhouse building high-power engines for both drag racing and pulling competition across the country!

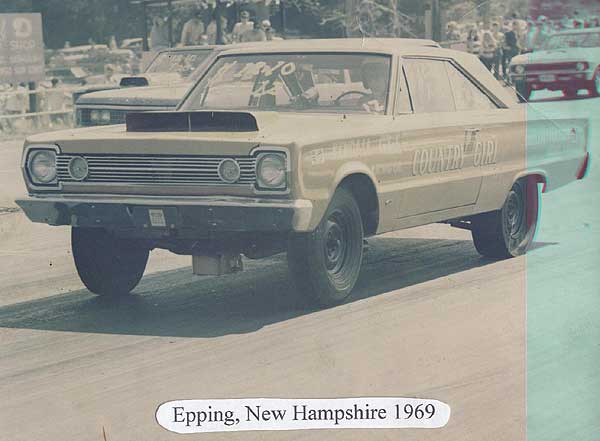

“It all started back in the late 1960s with John and Rodalyn Knox,” explains John Card, owner and VP of operations for Sassy Racing Engines. The couple were something of a sensation at their local drag strips in Super Stock and Funny Car racing; Rodalyn had proven to be the faster driver of the two and quickly became the de facto wheel-woman for the team, earning them no shortage of media attention in the highly male-dominated sport.

Over the team’s 31 years of active competition in drag racing and tractor pulling, their allegiance to the Mopar faction was unwavering. 426 Hemi-style engines powered their racing efforts throughout that time, and they would amass over 40 NTPA Grand National / Lucas Oil Pro Pulling League championships, dozens of European champions, and numerous state-level and regional championships along the way.

“Everybody kept coming to them and asking them what they were doing and what they were using,” John says. “So in the late ‘90s, they decided to start an engine building business. Our focus today is still in truck and tractor pulling engines, along with builds for drag racing, and the blown Hemi is our specialty. Brian [John and Rodalyn’s son] is the owner, tuner, and crew chief of the only tractor in world that’s powered by six supercharged 426 Hemis.”

While the Weare, New Hampshire shop has earned a well-deserved reputation for building some seriously brawny motorsport power plants over the years, the current team isn’t content to just watch their engines perform from the sidelines. “I came along seven years ago, and I brought my own drag racing program with me – John Card Racing,” Card tells us. “We have a blown alcohol dragster and two girls that drive it for us.”

John points out that this one car essentially functions as two different dragsters. “I’m actually the only person in the country that runs this way – same motor, transmission, and driveline, with two different bodies that have two different sponsors on them, and two different drivers that compete in two different series.”

Unsurprisingly, the car is motivated by Mopar power: A 526 cubic-inch Brad Anderson Hemi, built in-house by Sassy Racing Engines. “We race in the East Coast Pro Comp series – which is the same series that John and Rodalyn raced in with their Funny Car back in the ‘70s. The format is a 6.20 index on a quarter mile at up to 230 miles per hour. It’s a heads-up program and it’s like a Top Alcohol dragster, but it’s got a Roots blower on it instead of a screw-type or nitro. The other series we run in, Outlaw 660, is out in Ohio at Dragway 42. That’s an eighth-mile, heads up, run-whatcha-brung type of deal for dragsters.”

That Brad Anderson Hemi sports hardware that includes a Winberg crankshaft, a custom-grind camshaft from Comp Cams, Brad Anderson cylinder heads, a Hogan sheet metal intake, and a Kobelco supercharger. “We build all our fuel systems in house,” Card notes. “And we pair up the Sassy fuel system with the same type of Rage fuel pump that the pro teams run.”

That power plant is mated to a special heavy duty two-speed Powerglide transmission that was designed for nitro nostalgia cars, which routes the power through a coupler shaft into a Strange rear end. “The motor makes around 2,700 horsepower in this configuration,” Card adds. “And I believe the quickest it’s been in the Outlaw series was a 3.87 at 189 mph in the eighth mile.”

Switching between the two series with one car does require some minor setup tweaks, he explains. “Gearing, big tune-up changes, some adjustments to the wing, and some cockpit adjustments for the two different sizes of the drivers,” he says. But one thing that stays consistent across the board is the team’s confidence in Diamond pistons.

“We sell Diamond pistons in everything we’re doing in the tractor pulling, and we run them in all of our races. For years we used another piston manufacturer, and while we didn’t have any major problems with them, it was really time consuming to get what we needed made. We do a lot of specialty stuff where we’ll come up with our own designs and need someone to make a quality piece in a timely manner. We can get a new piston made in just a couple of weeks, whereas before we were waiting three or four months. And trust me, we’re putting these things through the ringer – in tractor pulling you put these engines through some pretty hard tests, and they’ve been coming out great. We’ve really haven’t had any problems in the past few years we’ve been running them.”

Last year the team barely missed taking home the title in the East Coast Pro Comp series due to an unforeseen circumstance. “That’s actually how the two different driver thing came along,” Card says. “For 2017, our main driver was Stacy McGlory out of Connecticut. Stacey’s good friend was getting married in the middle of the season and she couldn’t miss that. So we called up another driver, Angela Kinson, who races in Pro Mod – they’re about the same size, so we knew she would fit in our car pretty easily. Angela filled in for Stacy in July and she went out and won the race. We actually would have won the championship, but because the points are awarded to the driver rather than the team in that series, we came up a bit short. We knew that we would have to give up those points by swapping drivers, but we felt that it was important to make sure Stacy could share that moment in her friend’s life.”

With the new two-driver strategy, Card says they’ve got their sights on the title this year. “Now that we’re got two drivers running in two different series we shouldn’t need to have someone fill in again, so we’re definitely going after it to win a championship in one of them this year.”