Think of a forged piston like a blank canvas. It's sturdy and well crafted, but awaiting customized features that make it ideal for your engine. Here is a run-through of Diamond's popular piston upgrades to take your set of slugs to the next level.

Shelf-stock pistons offer all the core design features necessary to serve basic performance engine building requirements and some racing applications, but the demands of high-level competition frequently require extra attention–particularly with pistons. Diamond Pistons offers a broad range of custom piston upgrades specifically engineered to meet and exceed even the most demanding performance conditions, regardless of the application.

Among the spoilers in a piston’s operational work space, we recognize heat, engine speed, high cylinder pressure, lack of lubrication, friction, ring groove microwelding, detonation, pin loading and the overall violent nature of a highly loaded reciprocating environment. Superior pistons address all these concerns and more to ensure the highest level of dependable performance. As such, Diamond has developed innovative solutions for every type of piston challenge, and they are available as individual piston upgrades to suit your varying needs. Of course, they add cost to your piston choice, but you can cherry-pick only those upgrades that specifically support your requirements.

When ordering custom pistons, you have the option to specify a finished bore size, stroke length, rod length, compression height, block deck height, piston to deck clearance, compression ratio, and cylinder bore length. This establishes a basic piston configuration from which to build upon. From there you can select full round skirts, inboard pin bosses, and profiled or ribbed side reliefs. All this considers whether you need flat top, domed or dished piston crowns for your application. Finally, you can choose the desired piston material from 2618 alloy for most racing applications, or 4032 alloy for moderate performance use.

Wrist Pin Up-Sizing

Upgrading to an H13 tool steel wrist pin or a pin with more wall thickness is a great first step if you expect to employ supercharging, turbocharging or nitrous oxide injection. You can specify a broad range of pin wall thickness up to 0.330-inch for severe applications, generating massive cylinder pressures. Diamond Pistons pairs pistons with Trend Performance pins exclusively. Its G-Series pins are produced from chrome molybdenum 4130 thick-wall tubing. Superior to the common 1018 mild steel alternative, this alloy steel pin is ideally suited for use in naturally aspirated race engines

The H13 upgrade is a tool steel pin that is probably the best all-round material for most applications, especially in power-adder engines and Pro Stock drag racing engines. H13 pins have a Rockwell hardness value around Rc54, and readily accept a DLC (Diamond-Like Carbon) coating.

The next step up, the TP1-series pin, is not only exceedingly hard and extremely tough, but it is also DLC coated. These pins inhabit the Top Fuel, Funny Car and Pro Stock and Pro Mod ranks, where superior performance is mandatory. TP1 is an exceedingly tough material, tougher and more expensive than H13. It also boasts a lower coefficient of friction than other steels when used uncoated.

Pin Locks

When ordering custom pistons, you can specify single Spirolocs, double Spirolocs, wire ring locks or buttons. Your choice depends on your comfort-level with Spirolocs or wire rings. Buttons are often requested for use in power adder or nitrous applications. You can also choose offset piston pin bores if so desired. Custom pin fitting to a desired clearance can also be provided.

Gas Ports

Gas ports are an option you may wish to consider depending on your intended use. Gas ports are employed to direct combustion pressure to the back side of the rings to force them out against the cylinder walls. Two types are available: vertical and horizontal. Vertical gas ports are drilled from the top, straight down to the back of the top ring land. They are primarily used in drag racing applications where carbon buildup is minimal, and engines are frequently torn down. Horizontal gas ports are drilled horizontally in the top of the compression ring groove, so combustion pressurizes the ring via the crevice gap. They are equally effective and are less affected by carbon buildup. Gas ports are frequently used to improve ring seal in all types of competition engines. Depending on the piston and crown configuration, you can specify up to twelve gas ports.

Pin Oilers

All pistons can be upgraded to double pin oilers with banana groove slots on each pin boss. This provides two direct lubrication sources to each pin boss, and the banana groove slots are there to help distribute the oil around the boss to ensure broader lubrication coverage. This is quite useful in that it offers full time pin oiling whether the pin is loaded or not.

Crown and Skirt Thickness Milling

You have the option of specifying both crown and skirt thickness for your particular needs. As with other options, this is best done in consultation with a Diamond tech/sales agent to achieve best results. Thicker crowns and skirts are often requested for power adder applications such as supercharging and nitrous oxide injection. Diamond techs are well-versed in judging the correct specifications by application, and they will help guide your choices. 3D milling can also be applied to mirror the crown shape.

On the opposite end of the spectrum, internal milling of the skirt and crown area is also available to lighten pistons where applicable. A Maxi Lite feature can address all areas that can be milled for weight reduction without compromising strength, or you can specify internal milling in the skirt area and the under-crown surface. This will be done with awareness of your valve pocket requirements to ensure optimum piston integrity. When these operations are performed, you also have the option of specifying a counterweight clearance relief on the piston skirts and milling for connecting rod clearance.

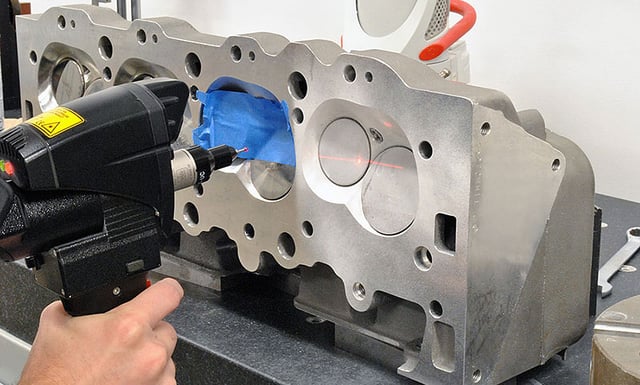

Cylinder Head Chamber Scan

If you provide a cylinder head or a sample piston, Diamond can scan the combustion chamber or the sample piston crown to provide the best possible piston crown configuration. This helps ensure perfect valve pockets of adequate depth and proper location. You can specify diameter, depth and valve angle at the desired location for both the intake and exhaust valves, and the sales/tech will alert you if you stray into dangerous territory around the ring grooves or with crown thickness. Crown configurations can also be adjusted if you need to address flame travel concerns.

Rings and Ring Grooves

You can position the rings where you desire within the limits of pin location and valve pockets. Custom pistons can be ordered without ring grooves or with groves in specified locations with desired sizing and ring land thickness. If your choices get the oil ring into the pin bore, an oil ring support rail will be provided with your ring set. You can specify ring size and groove width, as well as standard, high or low-tension rings.

Specialized Coatings

Multiple coating types are available to finish off your piston order such as anti-friction skirt coating, thermal crown coating, and durable hard anodizing. Piston coatings are a means to improve upon the base aluminum material in ways it could never perform on its own. While not impervious to abuse, they can greatly extend piston life in high-heat, high cylinder pressure environments, and reduce frictional wear.

Diamond’s ability to meet every aspect of any custom piston order has made it possible to obtain high-quality pistons for any application. If you brainstorm your basic needs ahead of time, you can fill out a custom order form online and they will alert you if anything is too far out of spec. You can also speak directly to a sales tech to really pinpoint the best possible configuration. When your tune is off and the engine is experiencing detonation or other harmful occurrences, superior pistons can provide the protection you need to avoid unwanted damage and poor performance.