The Ford Coyote is one potent power plant and with a set of Diamond pistons, its power-packed potential is substantially bolstered!

When Dearborn took the wraps off the Coyote V8 back in late 2010, it signified a new chapter in modern Ford performance. Though it remained close to the 4.6 DOHC mill it would replace in terms of physical dimensions and overall packaging, the Coyote featured numerous revisions that provided greater strength, enhanced efficiency, and a significant jump in output.

Boasting 412 horsepower and 390 pound-feet of torque when it debuted in the 2011 Mustang GT, the latest iteration of this naturally aspirated 5.0-liter power plant dishes out no less than 480 hp and 420 lb-ft in the 2019 Mustang Bullitt. While that’s more than enough grunt for most folks, for a lot of power-hungry gearheads it’s really just a foundation to start building from.

“As with any Modular motor, once enthusiasts and shops got their hands on the Coyote they immediately started tearing into them,” explains Dan Fons of Diamond Racing Pistons. “Forced induction has always been really popular with these engines, and literally within the first month that the car was out, people were blowing them up just trying to find the limitations of the factory stuff.”

Need 2,000HP capability? Check Out Diamond's MOD2K Pistons! HERE!

It didn’t take long to figure out where the new power plant could be improved. “Ford has a nasty habit of designing motors that can handle just enough to be lethal, but not enough for what these guys are really looking for,” Fons says. “And regardless of generation, we see a lot of issues that stem from the factory piston design.”

Here we’ll take a closer look at Diamond’s Coyote piston lineup and see how race-bred piston technology can have a profound impact on the modern 5.0’s durability and performance potential.

Factory Limitations

As builders started throwing boost at the Coyote, it quickly became apparent where there were some weak points in the rotating assembly. “The piston skirts are really thin, and what often ends up happening is that they’ll crack the top lands off if they run them lean and they get hot. That’s especially common for builds that are running power adders without intercoolers, and there’s a lot of people that run them on pump gas too, which doesn’t help the situation. We also see a lot of failures where the skirt collapses in, and either way, it’s a bad deal.”

Although a number of different variables could change the output ceiling for the factory bottom end, Fons notes that about 800 horsepower seems to be about the limit. “It certainly won’t live there forever, though,” he says. “And anything beyond that, you’re pretty much guaranteed to see a failure sooner rather than later.”

And as most of us are well aware, getting to that level of horsepower is easier than ever before. “The safe tunes you see on some of these blower kits are right around 600 horsepower, and they’ll pretty much live forever at that power level,” he says. “But as soon as you have 600 horsepower you want more, so a lot of these guys keep turning the boost up until they find that breaking point.”

Fons says sleeve failure is another common issue with the Coyote. “They’ll often break into a water jacket, or the actual sleeve itself will fail, and that’s a really big problem. Sometimes the pistons and rods don’t break, but the sleeve fails and the motor’s got to be pulled. At that point they’re either going to get a new block, sleeve it, or create some other plan of attack while the engine isn’t in the car. Regardless, they’re probably going to need pistons at that point.”

Better By Design

The first iteration of Diamond’s Coyote piston came out of the gate with an array of improvements over the factory design that focused on providing builders with the strength and durability they needed to reliably make big power.

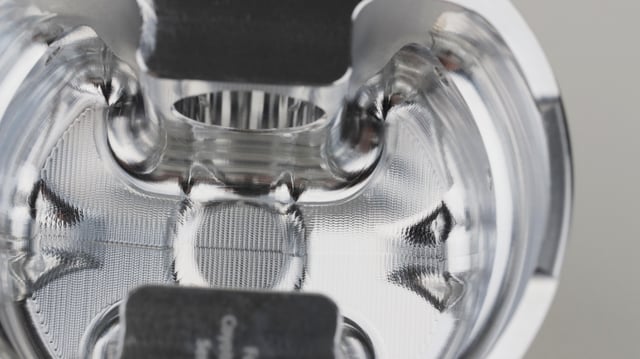

“It’s a full-round style of piston that we build out of 2618 grade aluminum and we beef everything up from that point,” Fons explains. “The top land height is increased, the ring pack gets some changes, and we put more material in the undercrown and on the skirts. The wrist pin we use is thicker than the factory piston as well.”

Those efforts yielded a piston that’s more robust that the stock piece from top to bottom. “It’s a tried and true design – it works,” Fons says. “We have the cutouts for the oil squirters in them, they’re quiet, and you can run them in tight tolerances without any issues. These are perfect for street-driven cars that are making significantly more power than stock – there’s a lot of surface area around the outside of the skirt and the ring pack we use is pretty thick. That helps control it and take heat out of that ring and put it in the cylinder wall.”

The 2618 aluminum used to create these forged pistons also provides significant strength improvements while keeping the weight down. “It’s a very dense alloy that has become an industry standard for most piston manufacturers at this point,” Fons says. “The material has higher heat properties, which gives us the ability to run it a little bit looser because it’s going to expand more. Along with better heat tolerance it also has good memory, so it can flex a little bit, if needed. We use 2618 in everything from these Coyote pistons to something like a Pro Mod or a Top Fuel type of setup. The material just works.”

Diamond also offers some upgrade options for builders who want to go above and beyond the standard Coyote street piston. “You can add skirt and crown coatings to any of the pistons in the Coyote line,” Fons notes. “And along with wrist pin upgrades we also offer gas porting, which helps with the overall ring seal on the pistons. In applications where there’s a power adder in the mix, the more force you can get behind that ring, the better the ring seal is. The only compromise is that you may wear the rings out faster because of the additional force on them.”

Generational Differences

Since the Coyote’s debut back in 2010, Ford has developed three distinct generations of the engine and its piston design in turn. While not radically different from one another, there are some distinctions between them which require builders to match the pistons they’re using with the Coyote generation of engine that they’re going in.

“Gen I and Gen II are pretty similar – if you look them side by side, they’re almost identical,” Fons says. “But there’s a couple changes that folks should be aware of. The compression ratio is different between the two, and the Gen II piston gets a little more dome. As far as strength goes they’re about the same, and the rods and crank carry over as well.”

The Gen III Coyote mill saw more substantial tweaks, however. Introduced for the 2018 model year, Ford made significant changes to the fueling system, introducing a direct injection system that works alongside a port injection system, while the piston bore diameter grew from 92.2mm to 93mm. “Everything on the piston changed,” Fons says. “Along with the larger bore the compression height is shorter, and piston itself has a higher compression than Gen II. It also has a recess on the top of the crown of the piston for the direct injection. It almost looks like a spark plug relief, but it’s actually a fuel bowl for that direct injection system.”

Fons says that despite the changes over the years, some of the same issues with the factory hardware remain. “Those skirts on the factory pistons are still failing and collapsing in, and that causes piston slap, which basically sounds like the end of the world.”

He notes that despite some flaws, the OEM design is a great starting point to develop a stronger piston. “We usually like to start with the factory piece as a template when we go to design a new piston. The OEM already spent millions of dollars developing this part, the least we can do is take it and make it a little bit better. There’s piston manufacturers out there who will eliminate some of the features of pistons like these – they’ll remove the fuel bowl, or change the actual bell shape, or they won’t 3D radius things. When you do that, the engine is not going to run the way the factory intended.”

Going Big

For builders who’re looking to venture deep into four-digit horsepower territory, Diamond recently introduced the Mod2k piston for all three generations of Coyote engines as well as the 4.6-liter DOHC Modular motors. These shelf-stock pistons are capable of handling 2,000 horsepower right out of the box, making them a great option for builds running big boost.

“This was sort of a follow-up to the LS2k line that we launched early last year,” Fons says. “The concept basically takes a unique forging that we made and beefs it up even further. We increased the top land size again, the ring pack gets some changes to allow for more expansion room, the skirts are coated, and gas porting is applied as standard. We also use what’s called an inboard box strut type of forging. As opposed to a conventional full-round forging, we run a shorter pin in it and we bring the pin towers in. By doing that we actually increase the strength of the piston even more.”

As with Diamond’s standard Coyote pistons the Mod2k line uses 2618 aluminum alloy, but with additional material in key areas like the crown, skirts, pin bosses, and wrist pin. Extra strutting ties it all together. “We rate them to 2,000 horsepower, and with the way that those blocks are, I can guarantee that these pistons will outlive block itself,” Fons says. “It’s an end-all solution.”